905 487 1521

905 487 1522

Race Towards Clean & Green Future Environment

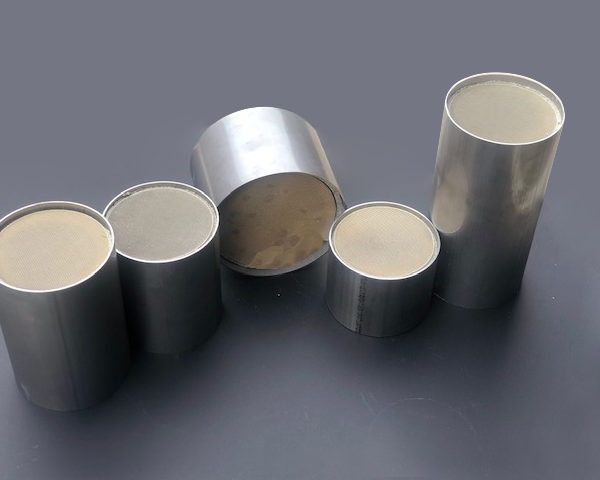

Three-Way Catalytic Converters

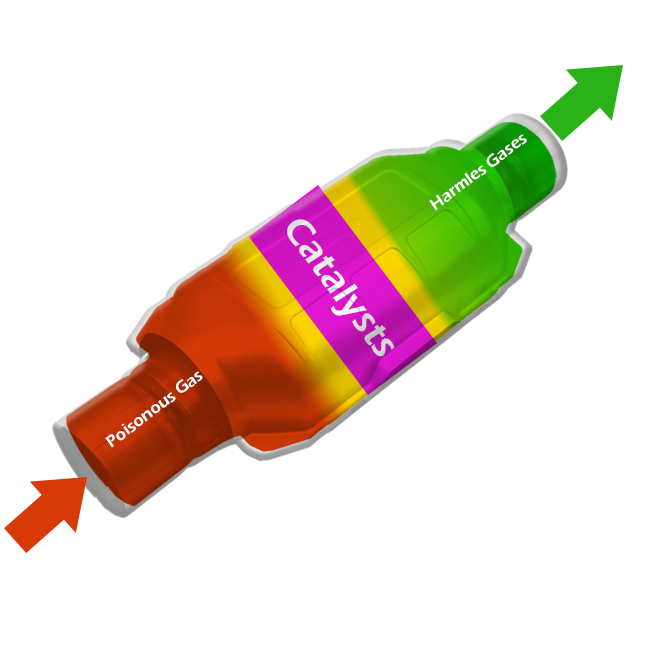

Primary function of Catalytic converter is to convert the harmful gases generated from combustion of fuel to harmless gases before releasing them in atmosphere

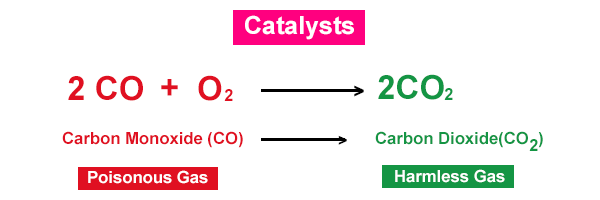

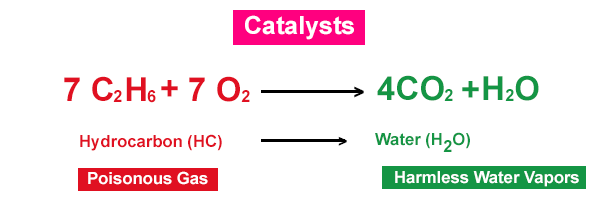

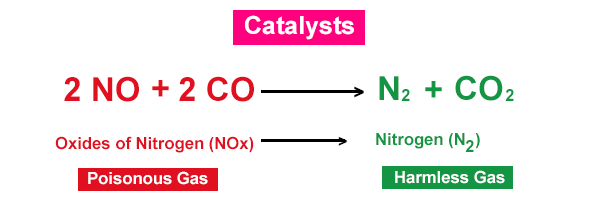

Three-way catalysts remove three pollutants out of an exhaust gas of internal combustion engines. mainly Hydrocarbons (HC) , Carbon monoxide (CO) and Nitrogen Oxides ( NOx), Referred as TWC ( Three Way Catalyst).